Robot Vision & Thermography

Machine Vision

Software

Reliable Vision Software solutions for

industrial automation in

manufacturing and logistics

industrial automation in

manufacturing and logistics

# Reliable

# Hardware agnostic

# Connectable

Precise pick & place

with 3D cameras

Precise pick & place

with 3D cameras

Precise pick & place

with 3D cameras

Precise pick & place

with 3D depth sensor

Precise pick & place

with 3D depth sensor

Precise pick & place

with 3D depth sensor

- 01

- 02

- 03

- 04

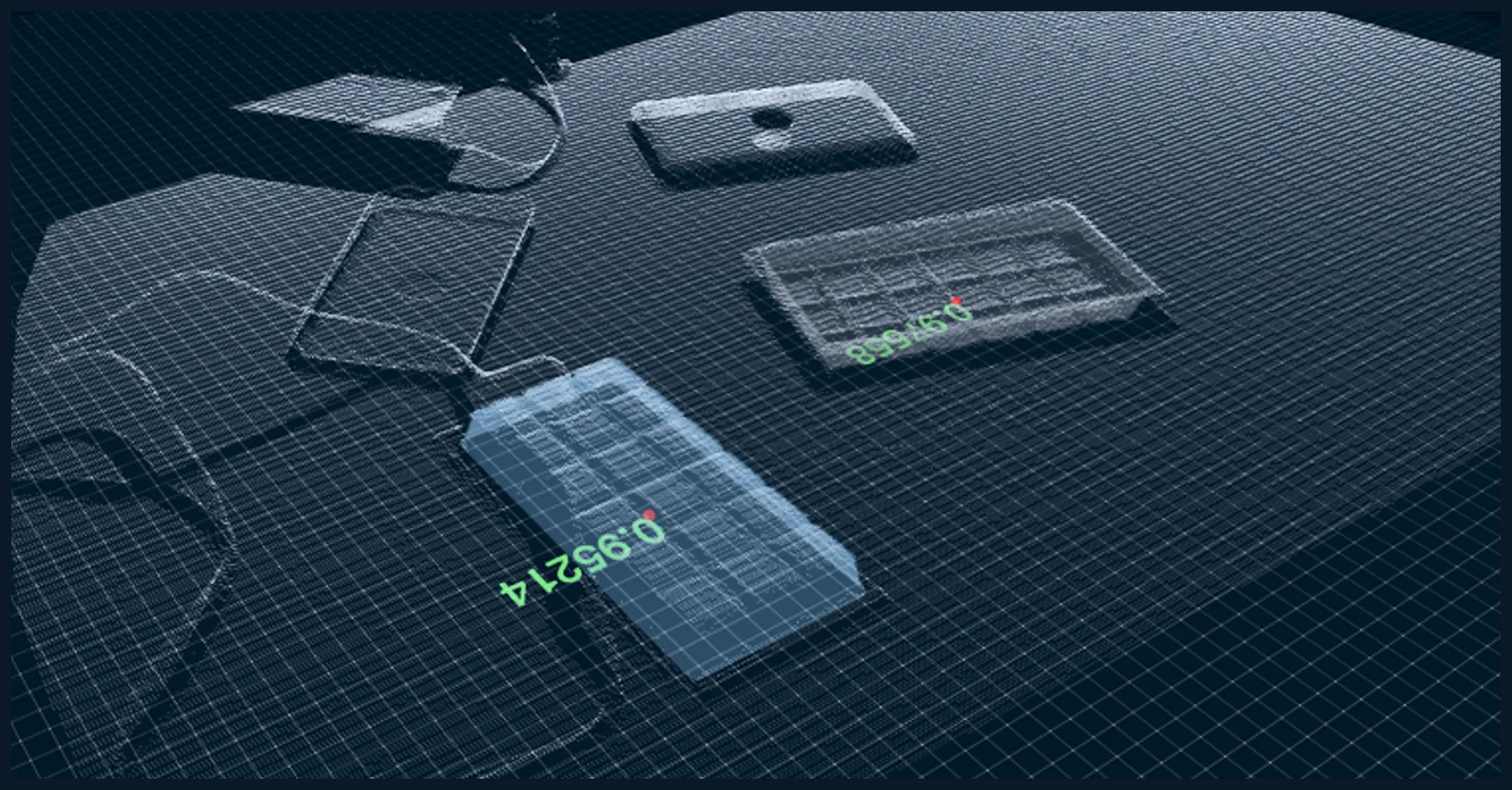

Use case 01

Depalletizing & machine tending

- Random location of the raw material

- Arbitrary number of variants

- Localization of target pallet

Use case 02

Handling of small specular parts

- Short cycle time

- No special illumination necessary

- Learns to adapt to changing lighting conditions

Use case 03

Sorting of small load carriers

- Distinguishes 10 variants

- Any spatial arrangement

- Precise stacking

- Depalletizing

Use case 04

Inline thermography for injection molding

- Detection of molding errors

- Monitoring of tool temperature

- Process analysis and auditproof storage of data

Use cases

Solutions for complex problems in industrial automation

Our software enables integrators to automate manual processes in unstructured environments or to replace expensive feeder machines.

Use Case Examples

- Depalletizing

- Machine tending

- Sorting

- Assembly

- Pick & Pack

Machine Vision Toolbox

Latest detection models

Pick & place applications in camera-guided robotics are not always the same. Machine tending requires maximum precision when placing objects. In goods picking, on the other hand, speed is more important. We provide detection models for every task.

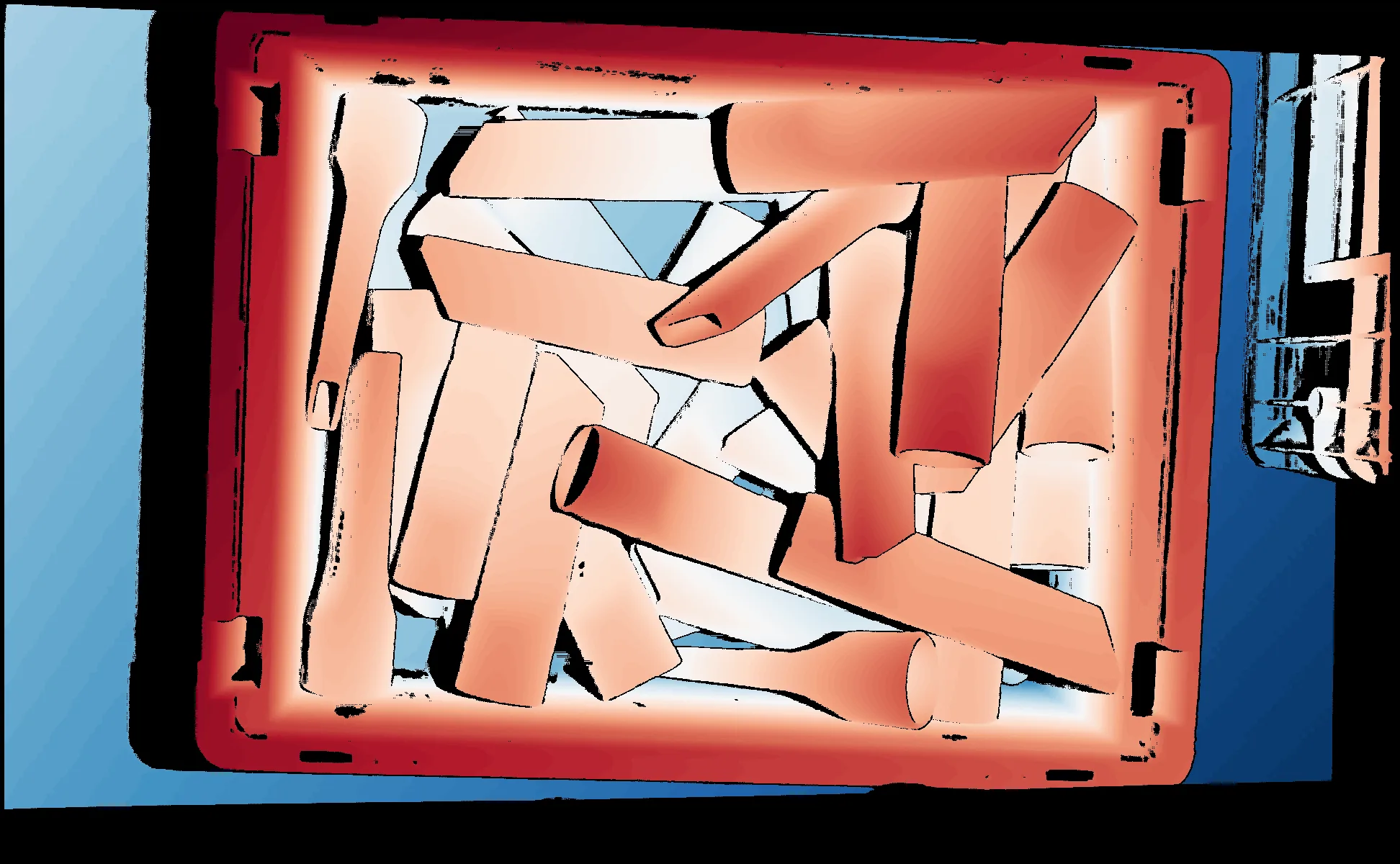

# Bin Picking

# Contour Picking

# Plane Picking

VATHOS

cloud_inference.py

1

2

3

4

5

6

7

8

9

10

11

12

13

2

3

4

5

6

7

8

9

10

11

12

13

# backproject with intrinsic info from product

K = np.reshape

(np.array(product['camera']['intrinsics']), (3, 3), 'F')

pcl = backproject

(0.001 * unpack_short(depth_img_compressed), K)

# run cloud inference

inference_url ='https://api.gke.vathos.net/workflow/camera'

files = {'files': open('./res/test.png', 'rb')}

values = {

'product': json.dumps(product),

'configuration': json.(configuration)

}

Hardware requirements

Modern infrastructure for any type of company

Our software is deployed on an industrial PC (edge), the cloud, or on a combination of both (hybrid). The system adapts to your company's IT — and not vice versa.

Hardware-agnostic

Any robot & camera

Hardware-agnostic

Any robot & camera

Hardware-agnostic

Any robot & camera

Cloud-only

Customers send recorded images for evaluation directly to the cloud.

Edge-only

A camera provides images directly to the edge device. Robots and other components of the system retrieve the result of the evaluation over the local network.

Hybrid

Compute-intensive operations such as training AI models are carried out in the cloud, and the evaluation runs on the edge device even without a stable internet connection.

Hardware agnostic

Industrial robots & cobots

Hardware agnostic

Industrial robots & cobots

Hardware agnostic

Industrial robots & cobots

Testimonials

Cost reduction and process optimization through the latest vision technology

Recent

Information & News

Information on practical use cases from production and logistics, new features and news about our company can be found in our blog.

Visit our blogPrecise Bin Picking – Open Problems and an Alternative Approach

Introduction

Precise picking from a box of bulk material for machine tending or assembly remains one of the most coveted applications in industrial automation. And the economic potential of a

Recent

Information & news

Information on practical use cases from production and logistics, new features, and news about our company can be found in our blog.

Visit our blog