Use case

Depalletizing a large variety of steel rods

THH Drehteile GmbH aimed to fully automate a manual manufacturing process — without making modifications to the transport containers and the way they are delivered to the machine.

Customer requirements

Random location of the rods inside framed Euro pallets

Arbitrary number of variants of partly specular rods

Uncertain placement of the pallet for processed parts

Customer benefits

Automation of manual labor for which nobody could be hired

Significantly increased throughput compared to the manual process

Components:

Robot

KUKA KR 120 R2700-2

GRIPPER

Goudsmit MS-8140405

HMS-PLAY50x2 MDC-50mm

Sensor

ZIVID 2

Vision SOFTWARE

Vathos Plane Picking

Edge Device

Sintrones ABOX-5000G1

PLC

Siemens SIMATIC

S7-1500 CPU

Integrator/Customer:

Components:

Robot

KUKA Agilus

GRIPPER

Pneumatic suction gripper

Sensor

BAUMER 2D VCXG-51M

Vision Software

Vathos Contour Picking

Edge Device

Advantech MIC-700

PLC

Siemens SIMATIC

Integrator/Customer:

undisclosed

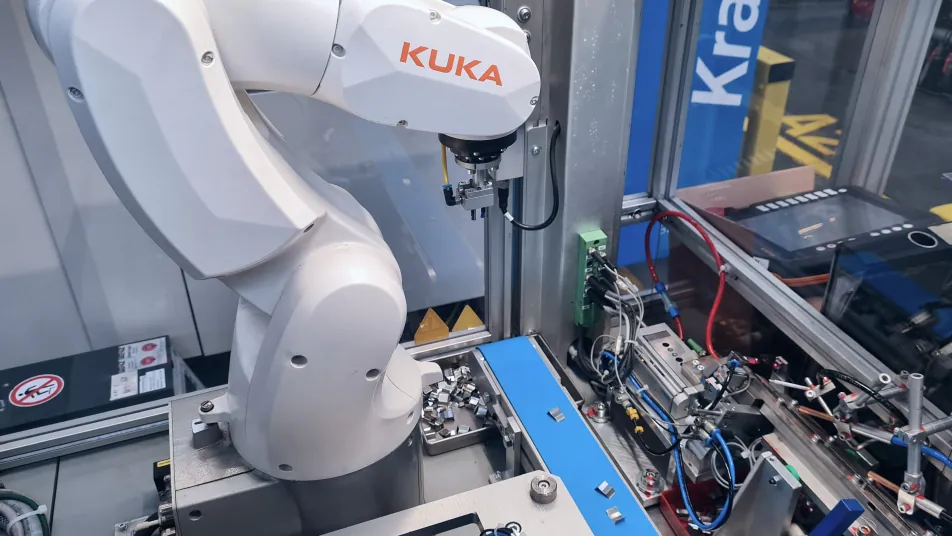

Use case

Fast picking of specular parts from a conveyor

At a household appliances manufacturer, a feeder machine that was responsible for separating raw parts and bringing them into a well-defined position would clog and interrupt production at regular intervals. Vision-guided picking off a conveyor bypassed all problematic mechanical equipment and boosted the overall reliability of the system by a large margin.

Customer requirements

Highly specular 10x20mm metal objects

Approx. 2.5s per pick

Sub-millimeter accuarcy

Operational 24 hours a day, 5 days a week

Customer benefits

Reduction of inadvertent interruptions by 70-100%

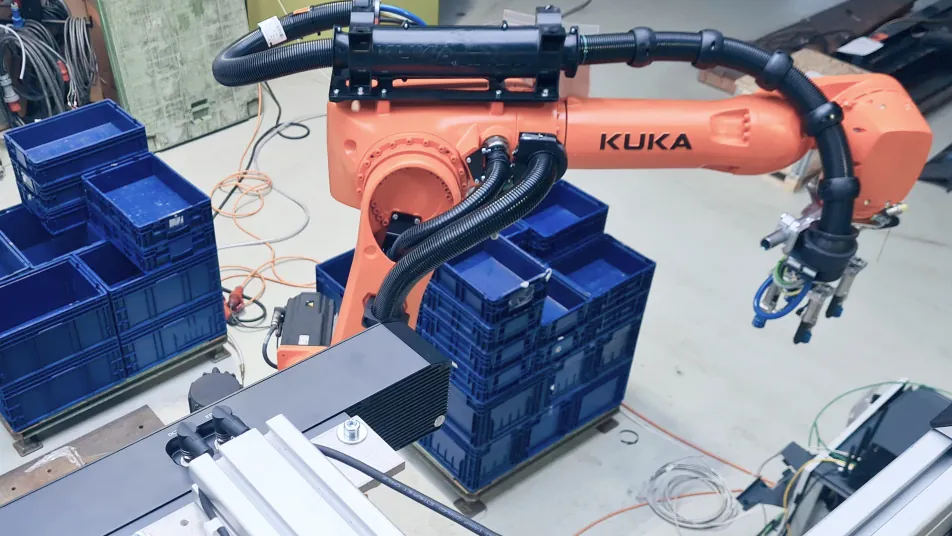

Use case

Sorting and stacking of small load carriers

A variety of empty load carriers coming from an assembly plant need to be sorted and stacked, each type on a separate pallet. The goal of the project was to process a subset of the incoming load on a branch of the main conveyor with an industrial robot. Our solution provides the key capabilities of distinguishing different box types, locating, and placing them on precisely-interlocking layers.

Customer requirements

Distinguish >5 different types

Sufficient throughput

Reliable building of stacks

Customer benefits

Reduction of manual, monotonous work

Components

Robot

KUKA KR 70 R2100

GRIPPER

Pneumatic suction gripper

Sensor

Zivid 2

Vision Software

Vathos Plane Picking

Edge Device

DELL Precision

PLC

Siemens SIMATIC

Integrator/Customer:

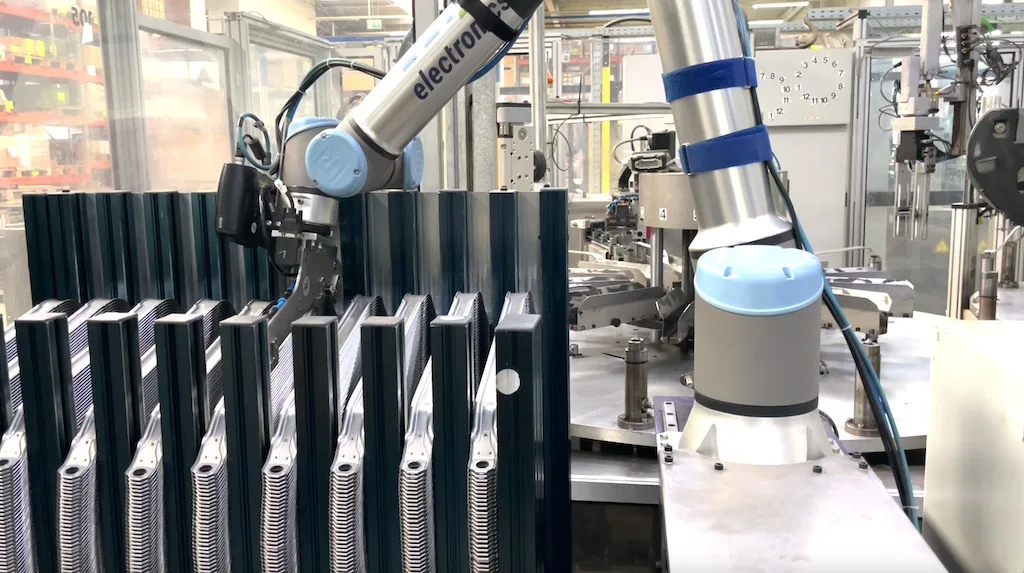

Components

Robot

Universal Robot UR10e

GRIPPER

Component-specific

Sensor

ZIVID2+ M60

Vision Software

Vathos Plane Picking

Edge Device

Advantech MIC-770

PLC

none

Integrator/Customer:

Use case

Machine tending of tank clamping straps

Manual loading of tank clamping straps has been replaced by two camera-guided cobot systems that retrieve eleven variants from a magazine. The high placement accuracy requires permanent adjustment of the gripping points by the Vathos vision system.

Customer requirements

24h operation, 5 days a week

Flexible integration into a special machine

Reliable, autonomous process lasting for hours

Customer benefits

Two people are free for other tasks

High employee satisfaction

Stable, predictable, yet flexible process

Use case

Inline thermography of molded plastic parts

Incorrect temperature distributions on the tool are detrimental to quality in injection molding. We monitor the tool temperature indirectly by obtaining images of the part with an infrared camera instantly after ejection from the machine. Our software detects common error classes such as partial or complete failure of the cooling system, incomplete filling of the mold, or bead wire break.

Customer requirements

Integration into existing process

High variance of part types

Customer benefits

Holistic quality control

Independent of injection molding machine vendor

Inexpensive compared to cooling water measurement